Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 16652801818,. Or call +86 16652801818 directly.

*We respect your confidentiality and all information are protected. We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.

Are you tired of unreliable sawmill equipment letting you down on crucial projects? Your productivity—and profits—could be in jeopardy. But with the right, durable portable sawmill, you’ll turn logs into usable lumber more efficiently, unlocking serious value for your business.

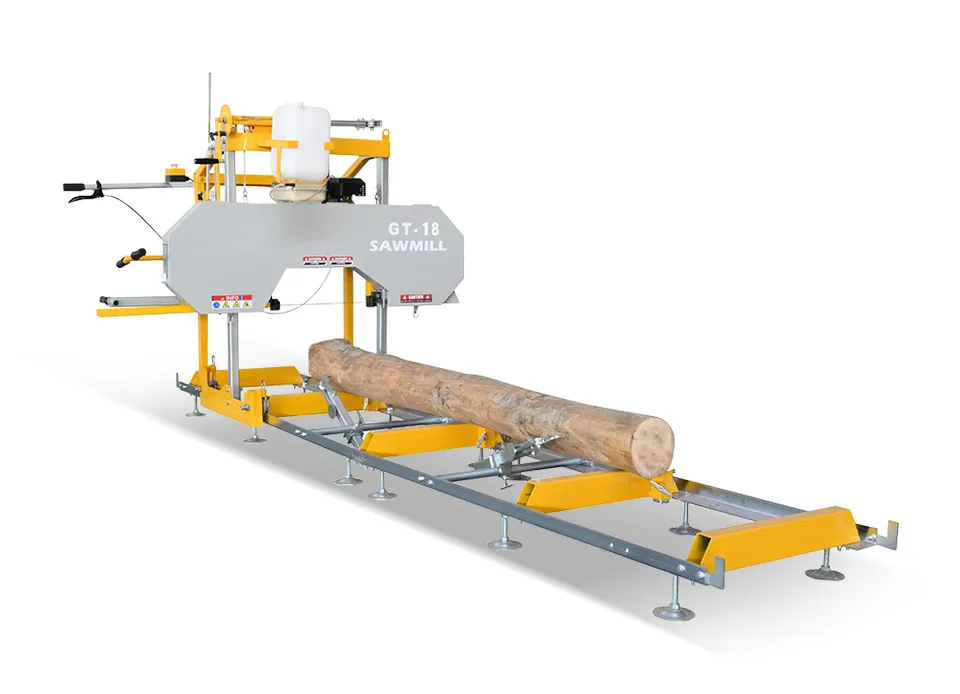

A sawmill—especially a portable sawmill like those produced by leading manufacturers—cuts logs into lumber using advanced saw blades and robust mills. The right choice delivers durability, high load capacity, user-friendly features, and dependable performance for construction, farming, forestry, rentals, and government projects.

A sawmill processes logs into lumber by utilizing a powerful saw blade, often mounted on a mill carriage. A portable sawmill offers flexibility, allowing users to take the mill to the log site for efficient, on-the-spot lumber production, minimizing handling and boosting yield.

A traditional sawmill uses machinery like a bandsaw or circular saw to cut logs into usable boards, beams, or slabs. Portable sawmills, such as the ones manufactured and supplied by our construction equipment manufacturing plants, bring this milling capability out of the factory and into the forest, the farm, or any construction site.

Key Features:

This process means that instead of transporting heavy logs, you transport and set up your portable sawmill—saving on logistics and delivering immediate conversion of trees to 2x4s, cants, or live-edge tables.

Durability, load capacity, and power system strength are vital for construction. Portable sawmills enable contractors to create custom lumber on-demand—reducing costs, avoiding supply chain delays, and allowing for project-specific dimensions.

| Feature | Benefit to Contractors |

|---|---|

| Power system (horsepower) | Handles oversized logs, increases output |

| Ease of use | Quick setup; minimal training required |

| Load capacity | Enables batch processing for big projects |

| Steel bed | Rugged support for heavy construction logs |

The HB series offers versatile power options with gasoline engines (6.5HP–15HP) for outdoor use and electric motors (5.5KW–7.5KW) for eco-friendly tasks. Models like HB26G (9HP) and HB31G (15HP) provide high torque, while HB26E/HB31E offer consistent indoor power. The HB18G, featuring Briggs & Stratton or Honda engines, ensures reliability with manual start systems and stable displacement (200cc–420cc) for efficient performance.

The HB series features cutting capacities up to 31″ width and 110″ length, handling logs like HB31G (790×178×2794mm). With blade speeds of 17m/min and safe cutting rates of 13–15s/m, it ensures fast, precise cuts. The 22mm tooth spacing and 480mm blade wheels optimize durability. The HB18G supports thin cuts (20mm) and lifts up to 480mm height, perfect for detailed woodworking. Track sizes (4000×1030mm) and a 1200lbs winch system enhance stability for complex cuts.

The HB series, including models like HB18G (140–160kg), is designed for easy transport, fitting into standard shipping containers (176pcs/40″HC). Larger units like HB31G retain mobility with modular frames. Double-track configurations reduce ground pressure, while lightweight yet durable construction and 4-piece frames ensure quick assembly. These features make the HB series ideal for contractors needing a balance of power, precision, and portability.

For example, when building timber frames or custom cabinetry on-site, a portable sawmill delivers flexibility and saves significant costs compared to buying pre-cut lumber. Learn more from our sawmill solutions page.

sawmill

On the farm, a portable sawmill transforms fallen or cut trees into usable lumber for fencing, sheds, barns, or machinery repairs—all right at the source.

Farmers can also resell lumber as an additional revenue stream, benefiting from the sawmill’s flexibility and cost-effectiveness. Our portable sawmill lineup is specifically designed for tough farm conditions.

Landscaping and forestry professionals need mills capable of turning logs into valuable lumber efficiently. Portable sawmill systems are ideal for remote woodland use, actively supporting sustainable forestry and landscaping projects where logs are plentiful but transporting them is a challenge.

Case Study: One forestry company used a fully hydraulic portable bandsaw mill to process oversized logs directly in the forest, producing live-edge slabs for tables and construction. Not only did this cut transportation costs, but it also enabled rapid response to tree falls or selective harvesting. For more landscaping and forestry machinery, see our skid steer loader selection.

Rental companies benefit by offering portable sawmills that are durable, user-friendly, and low-maintenance. Construction contractors, forestry crews, and even government buyers often prefer renting rather than owning a sawmill for short-term or specialized projects.

By providing reliable, high-quality equipment, rental companies expand their customer base and capture demand across farming, construction, and public sectors. Explore our range of portable sawmills for rental fleets.

For public agencies and tenders, factors like compliance, ease of operator training, and consistent performance are vital. Applications include disaster response, infrastructure projects, and public works.

Our manufacturing plants ensure equipment meets rigorous specifications for government buyers. Related solutions for public projects are available in our loader backhoes and mini excavators ranges.

Durability starts with high-quality steel beds, industrial sawhead construction, and robust crankshafts—all designed to handle the harshest job sites, from muddy woodland to uneven construction floors. Our sawmills are built in the USA for tough conditions.

Reliable mills mean less downtime and lower repair costs. Our sawmills feature low-maintenance bearings and easy-to-sharpen blades, reducing total cost of ownership.

“The easier it is to use, the more productive my crew is—every hour saved goes straight to the bottom line.” — Construction Contractor, Midwest

| Model | HB26G | HB31G | HB26E | HB31E |

| Power | Gasoline 9HP(LIFAN, Manual start) | Gasoline 15HP(LIFAN,Manual start) | Electric Motor 5.5KW | Electric Motor 7.5KW |

| Displacement | 301cc | 420cc | 400V 50HZ 3phase | |

| Frame | 4pcs | 4pcs | 4pcs | 4pcs |

| Cutting capacity | 660*178*2794mm(26″*7″*110″) | 790*178*2794mm(31″*7″*110″) | 660*178*2794mm(26″*7″*110″) | 790*178*2794mm(31″*7″*110″) |

| Blade size | 3690*34*0.9mm(145″*1-1/4″*0.035″) | 3960*34*0.9mm(156″*1-1/4″*0.035″) | 3690*34*0.9mm(145″*1.25″*0.035″) | 3960*34*0.9mm(156″*1-1/4″*0.035″) |

| Standard track size | 4000×1030mm(157″×40.5″) | 4000×1030mm(157″×40.5″) | 4000×900mm(157″×35.4″) | 4000x1030mm(157″×40.5″) |

| Packing | 2150×570×830mm | 2150×570×830mm | 2080×610×810mm | 2150×610×810mm |

| Safe cutting Speed | 13-15s/m | 13-15s/m | ||

| Blade speed | 17m/min | 17m/min | ||

| Distance teeth | 22mm(0.86″) | 22mm(0.86″) | ||

| Blade Wheel Dia. | 480mm(18.8″) | 480mm(18.8″) | ||

| Dimension | 4064*1778*1800mm(160″*70″*71″) | 4064*1778*1800mm(160″*70″*71″) | ||

| Weight | 315/355kg | 352/380kg | ||

| Model | HB18G |

| Standard Power | Briggs Stratton,6.5HP Manual start GX200 Honda,7HP Manual start |

| Displacement | 200cc |

| Cutting capacity | 460*170*2780mm (18″*6.7″*109″) |

| Frame | 4pcs |

| Blade size | 3050*32*9mm(120″*1-1/4″*0.035″) |

| Standard track size | 3600×607mm(141″*23.8″) |

| Winch | 1200lbs |

| Min.cutting thickness | 20mm(0.78″) |

| Max.lifting height | 480mm(18.8″) |

| Packing | 1400×550×510mm |

| Weight | 140/160kg |

| 40″HC | 176pcs(EU market) 165pcs(N/A market) |

What’s the difference between a portable sawmill and a stationary sawmill?

A portable sawmill can be moved to the location of your logs, saving transport costs and time. Stationary sawmills require bringing logs to the mill site.

Which sawmill blade should I choose for best lumber quality?

Bandsaw blades are preferred for fine cuts and minimal waste. Keep blades sharpened for smooth lumber.

How long does it take to set up a portable sawmill?

Setup can take as little as 30 minutes. User-friendly design means minimal tools and fast adjustments.

Are portable sawmills suitable for oversized logs?

Yes, many commercial-grade mills handle oversized and diameter logs, with adjustable sawheads and steel beds.

What maintenance does a portable sawmill require?

Regular blade sharpening, checking lubrication, and cleaning the mill and steel bed are the main tasks. Hydraulic systems may need periodic inspection.

Can I cut hardwood and softwood logs with the same mill?

Absolutely—modern portable sawmills can handle various wood densities and lengths, as long as the blade and power system match the job.